Risograph printing is a stencil-based, eco-friendly printing process known for its vibrant colors, unique textures, and affordability in medium to large print runs. Originally developed in Japan, it uses soy-based inks and a process similar to screen printing, layering one color at a time through a master stencil. Popular among artists, designers, and small publishers, Riso printing is valued for its distinctive aesthetic—imperfect alignments, bold colors, and a tactile, handmade quality.

What Is Riso?

Risograph printers were developed in the late 1980s in Japan by Riso Kagaku Corporation as a cost-effective solution for high-volume office printing, this process was inspired by earlier technologies like mimeograph machines but has since evolved into an artistic medium. Still used by small to mid-size organizations, artists and designers have adopted riso printing for its unique, vibrant and paint-like aesthetic. Speedy, efficient and eco-friendly, risograph printers employ a process similar to screen-printing with stencils and layers of ink.

Risograph printing uses a digital duplicator that creates a stencil (called a "master") for each color layer. The machine wraps the master around an ink drum, which then pushes soy-based ink through the stencil onto paper. Each color is printed separately, so multi-color prints are produced by layering colors one at a time—requiring precision and planning, much like screen printing. Because of this, slight misalignments, overlaps, and texture shifts are common.

Stencils are created especially for each drum and cannot be used on another drum. Multicolored prints are produced by switching out the drums, overprinting, and again running the paper through the Riso. One color or two are printed at a time.

Stencils are created especially for each drum and cannot be used on another drum. Multicolored prints are produced by switching out the drums, overprinting, and again running the paper through the Riso. One color or two are printed at a time.

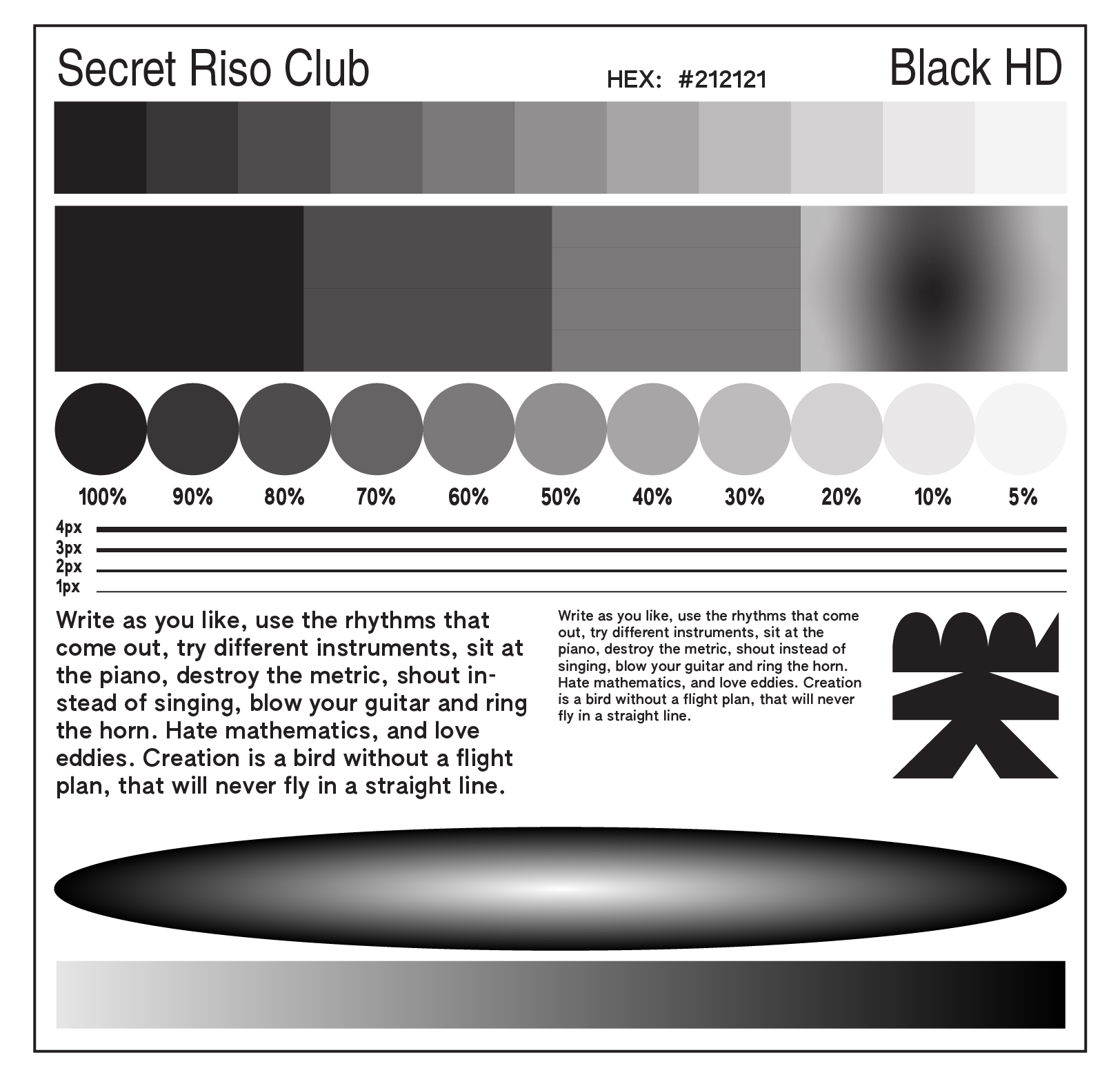

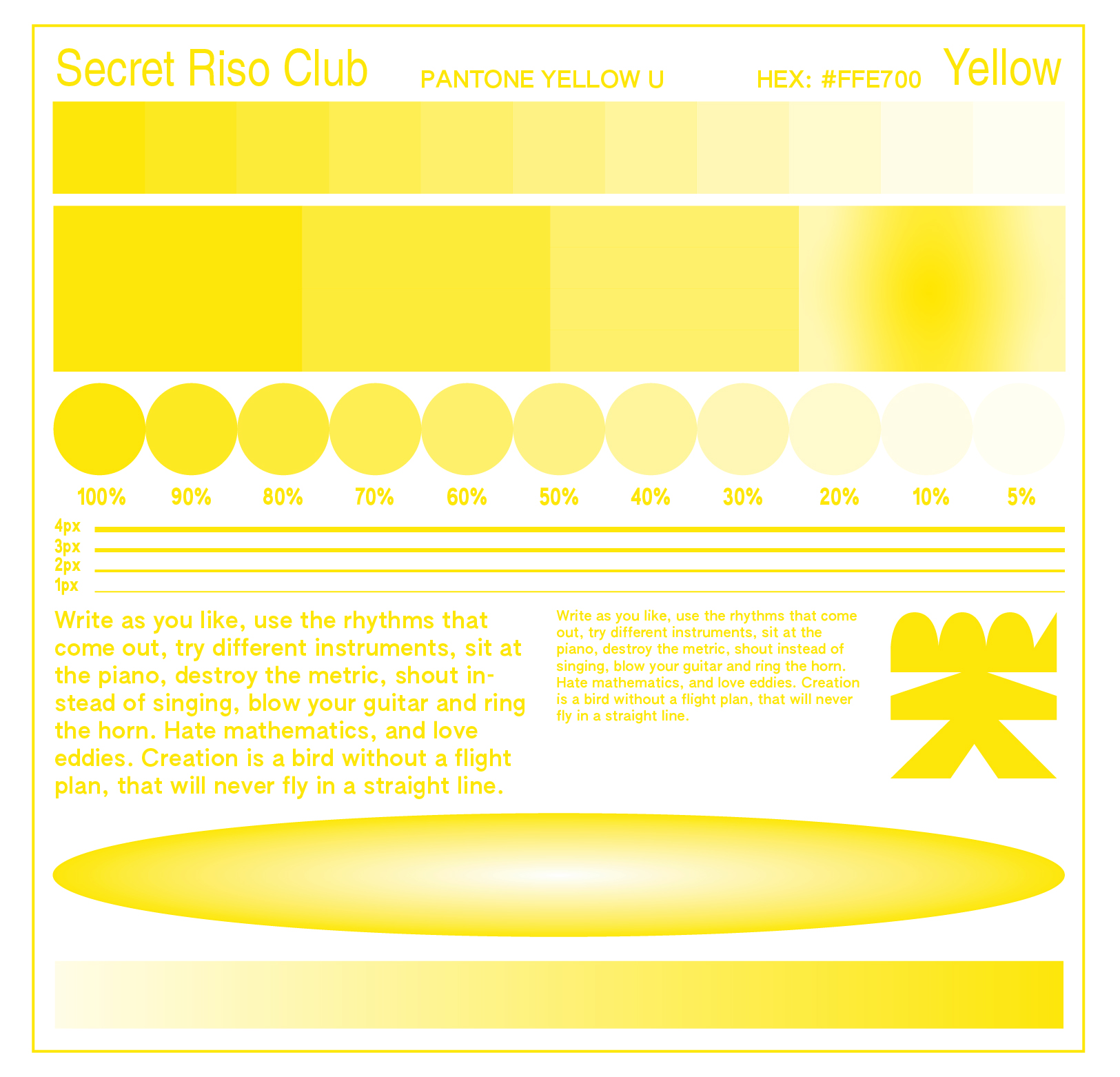

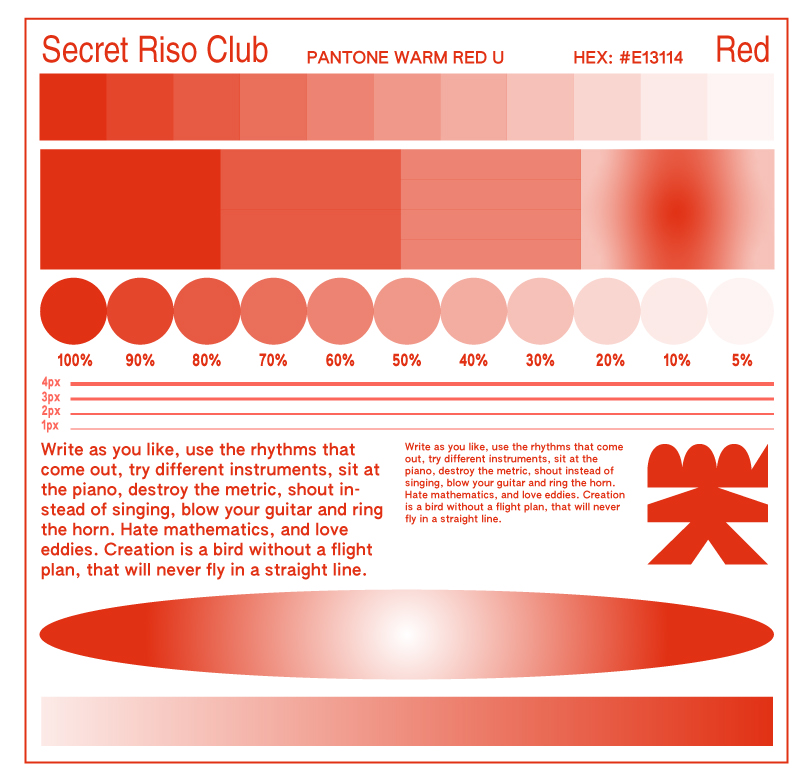

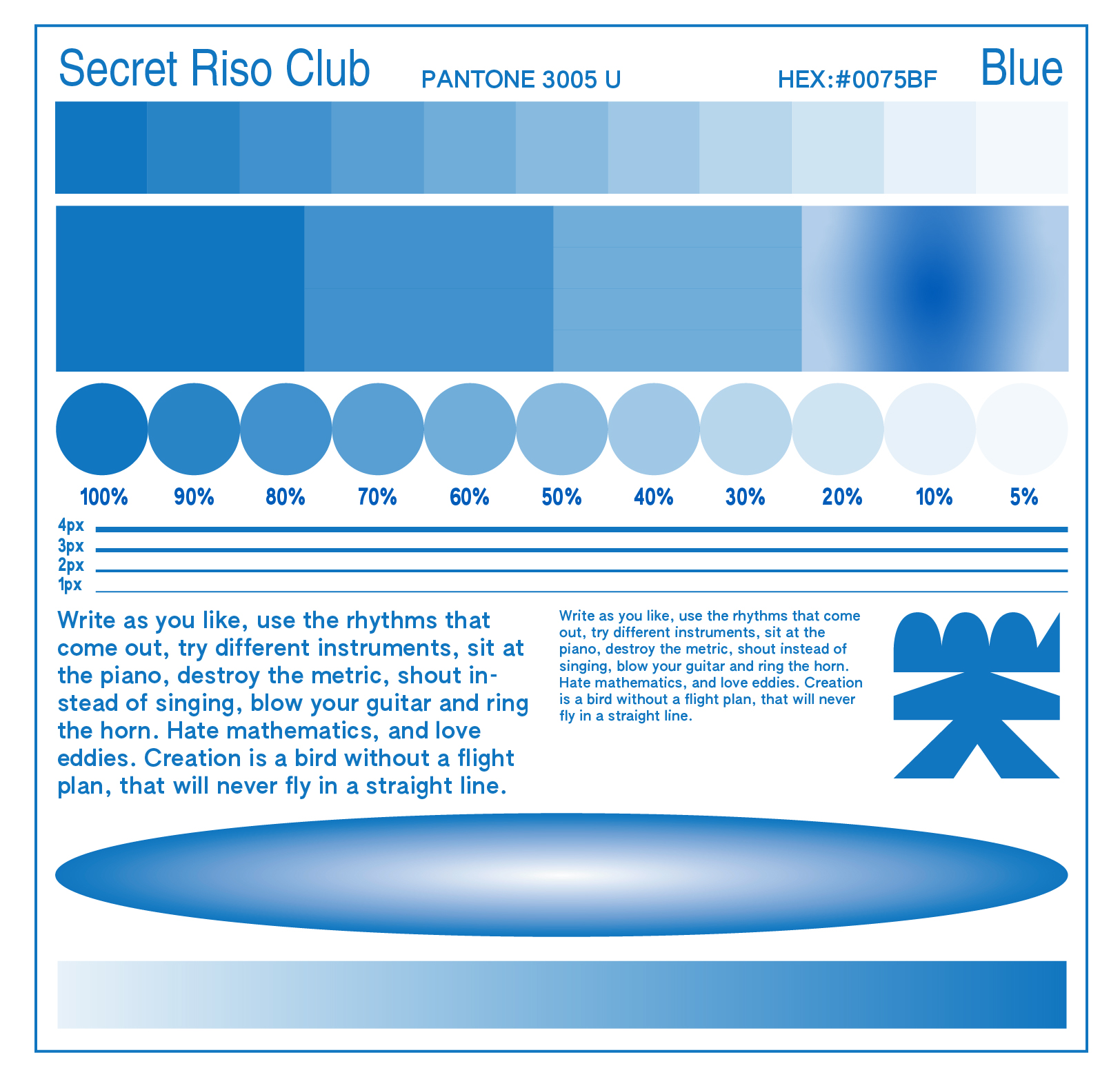

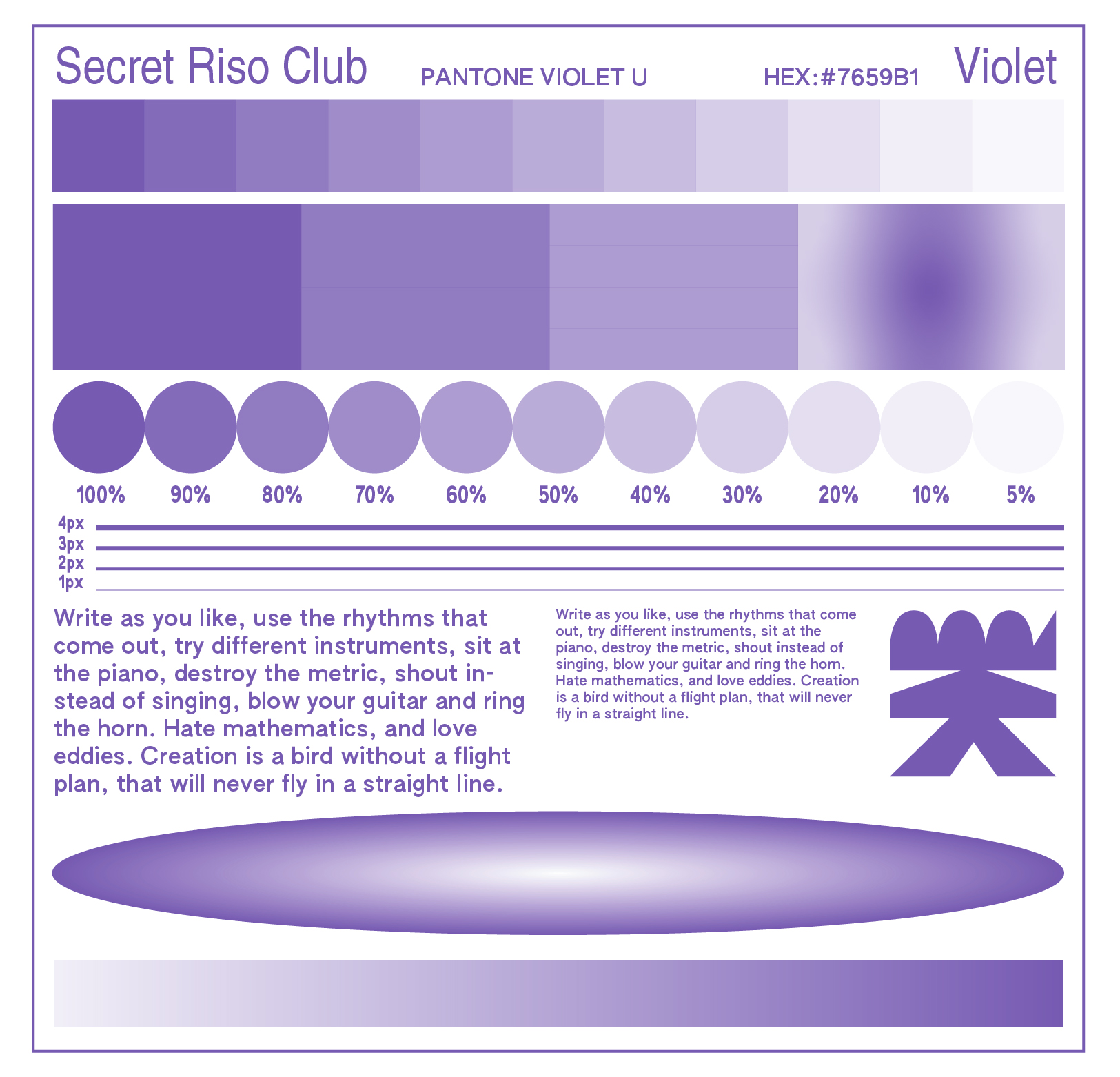

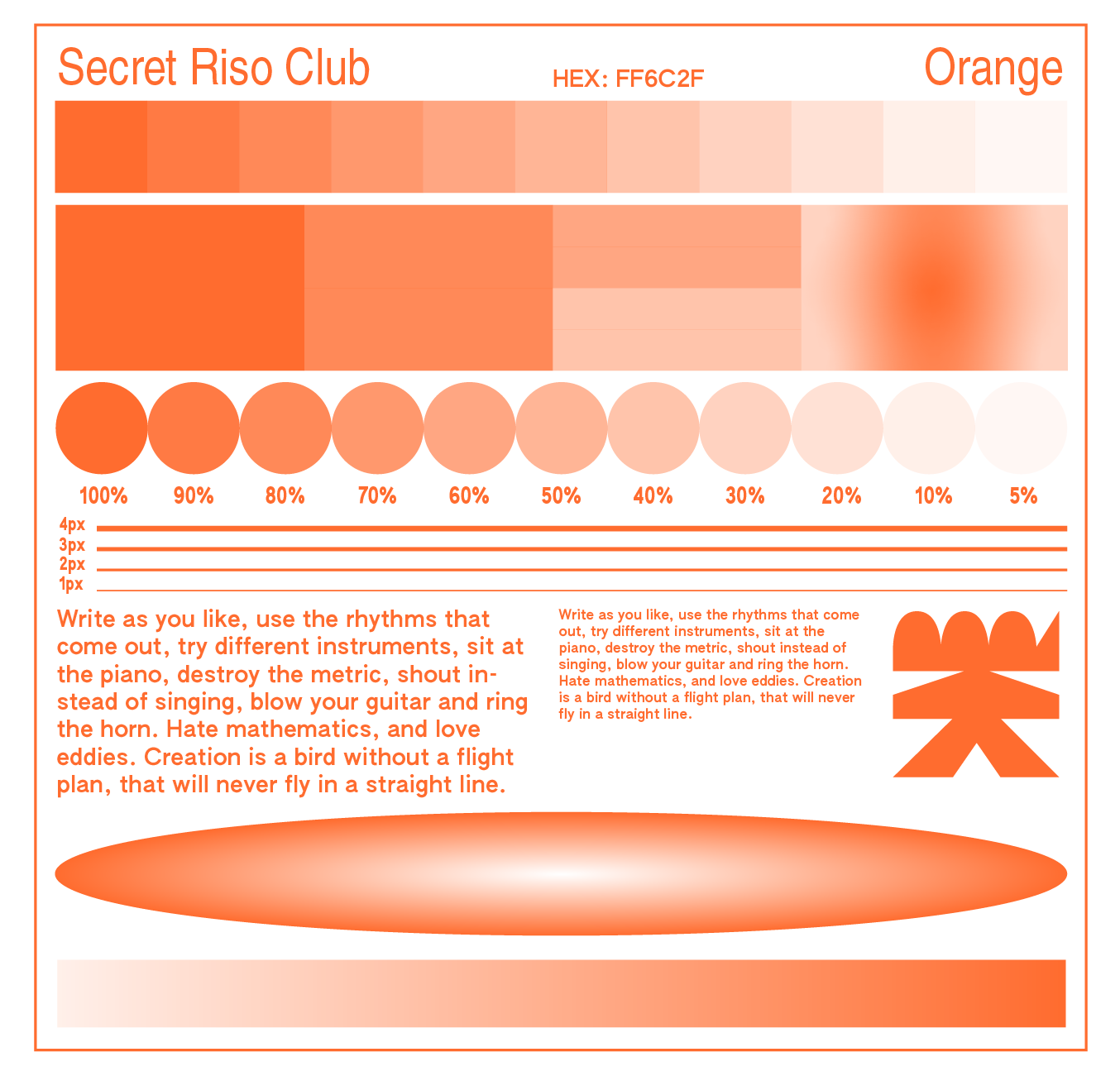

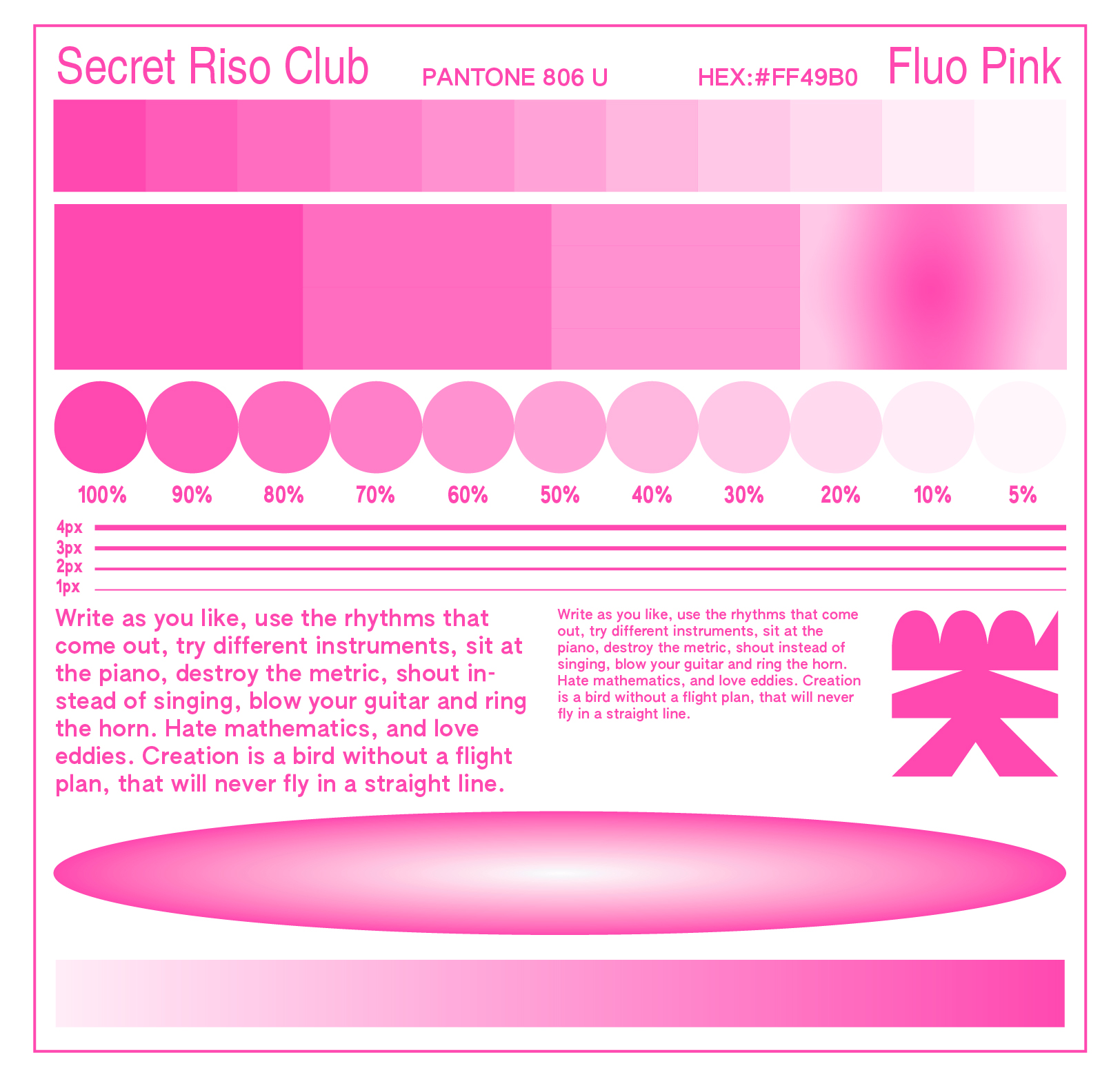

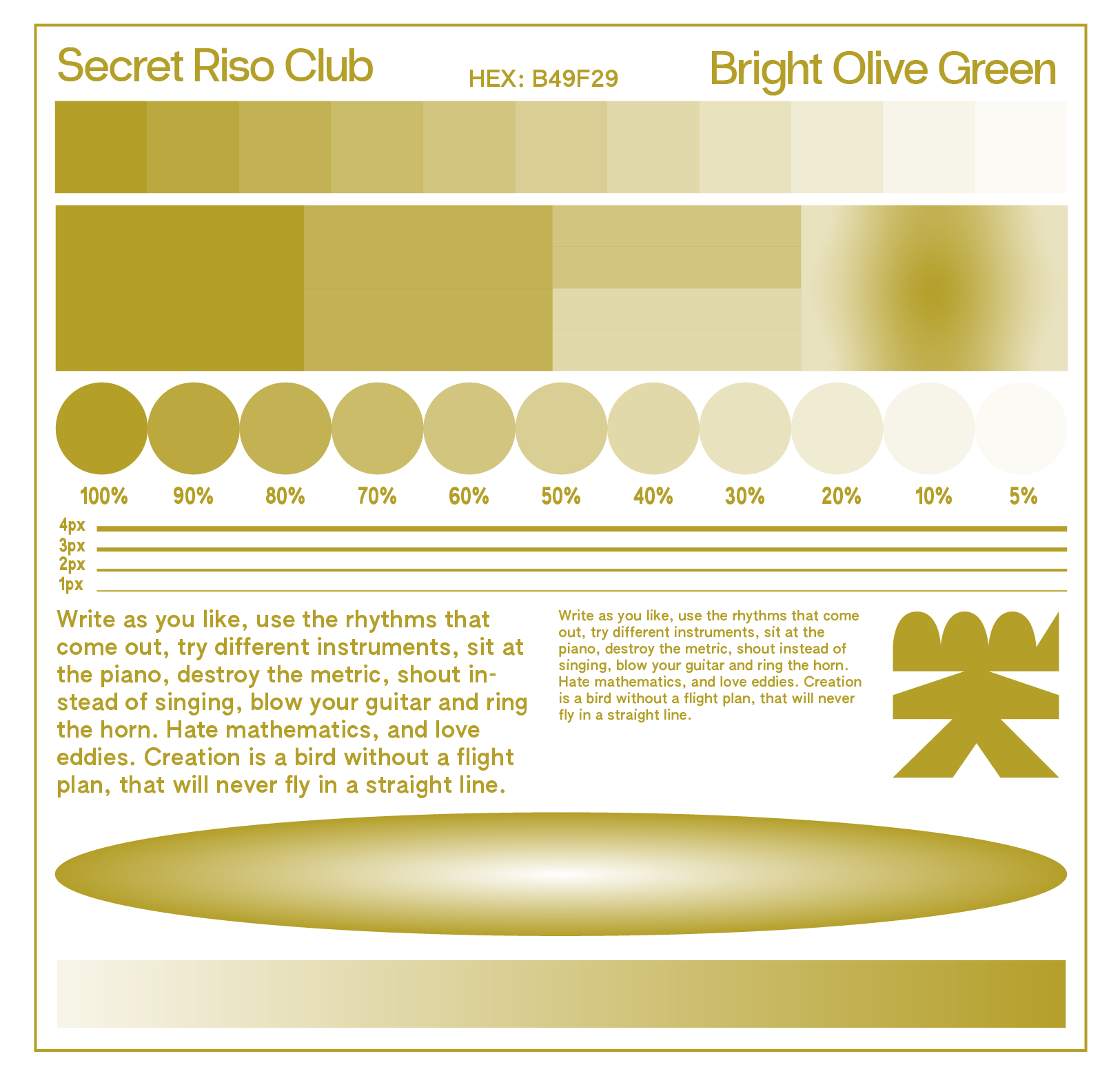

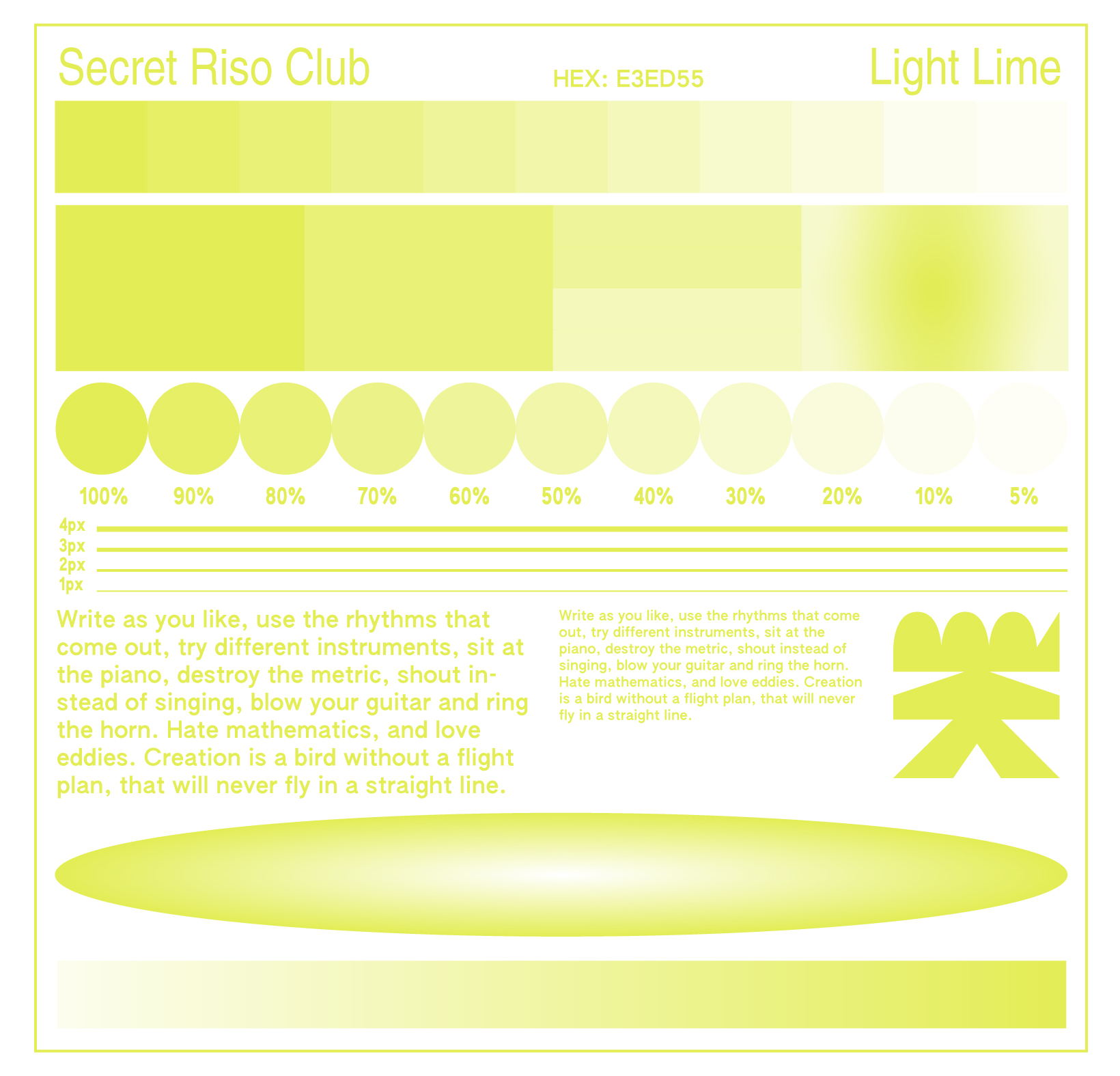

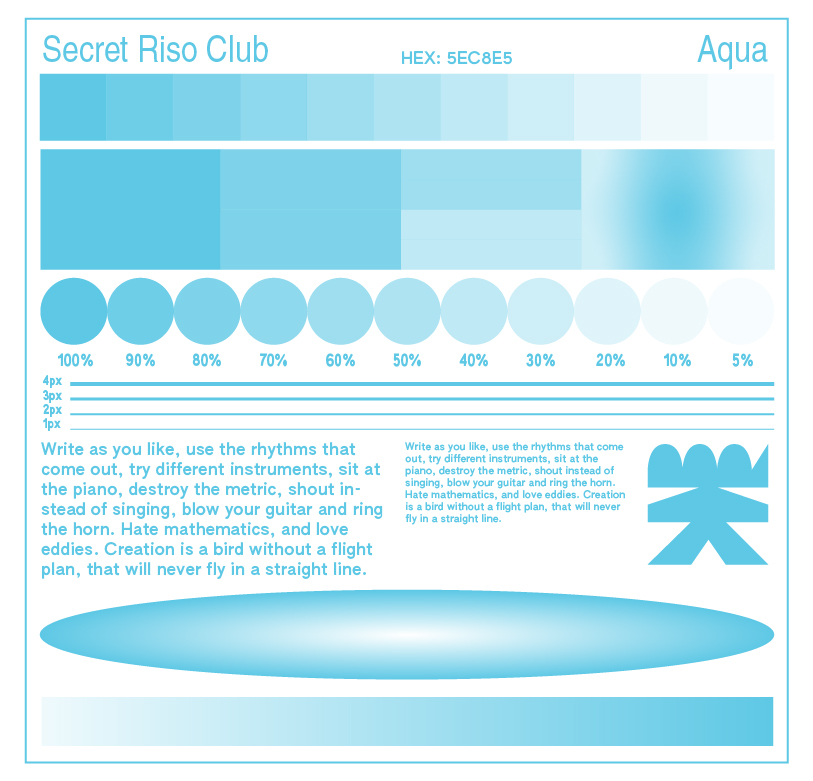

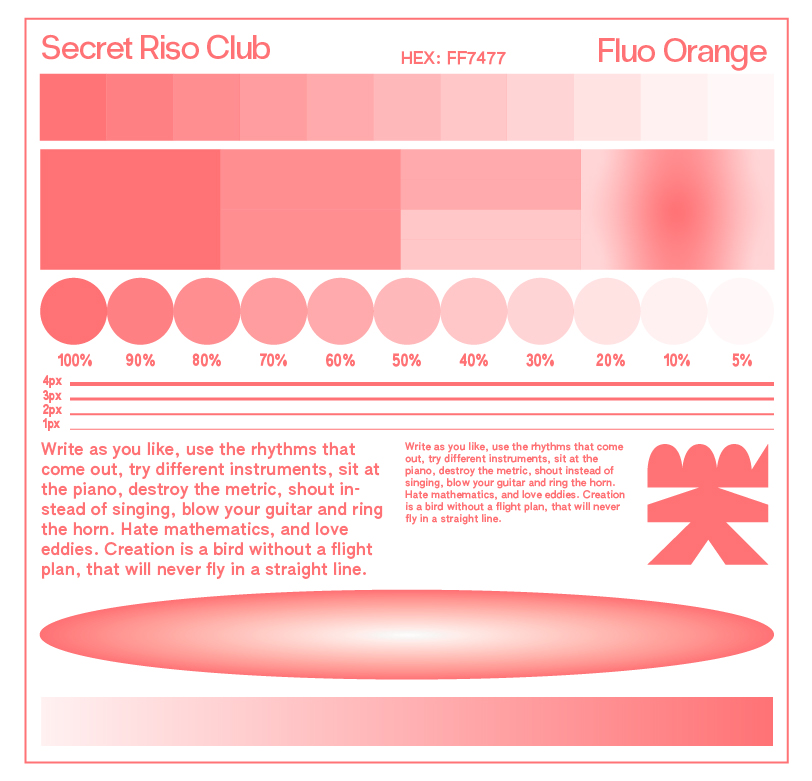

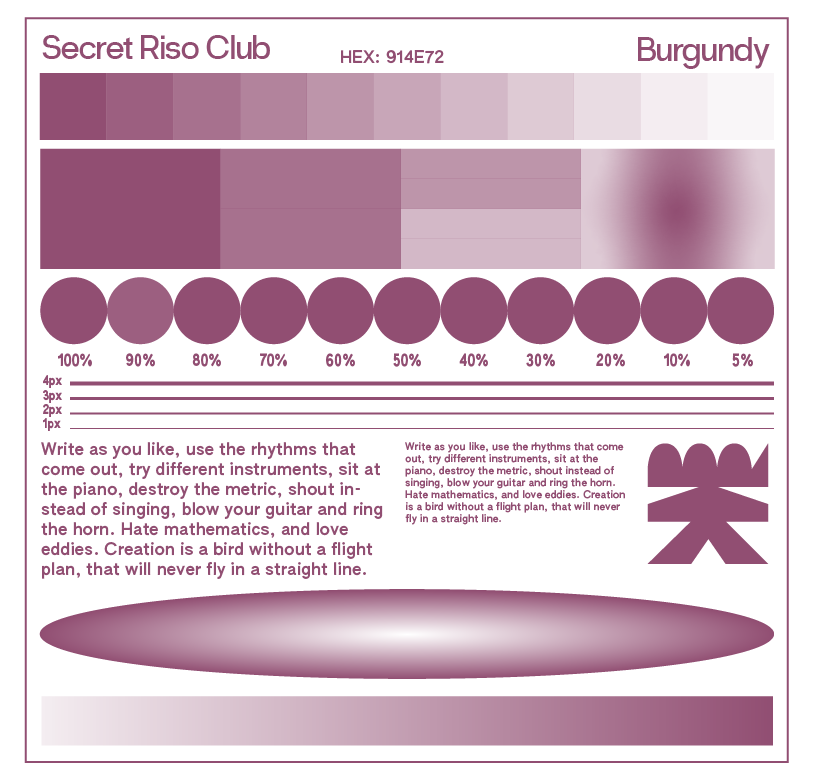

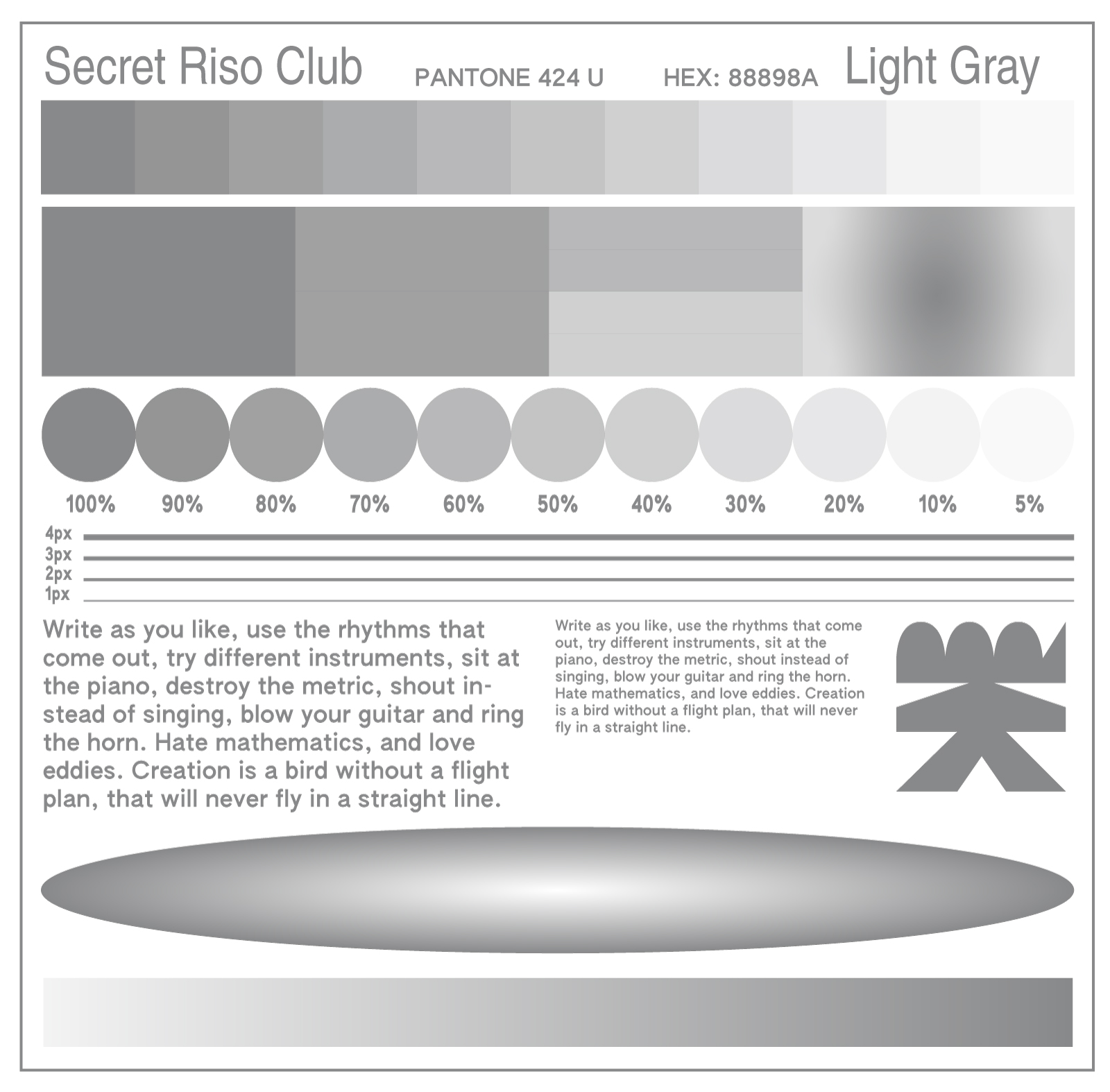

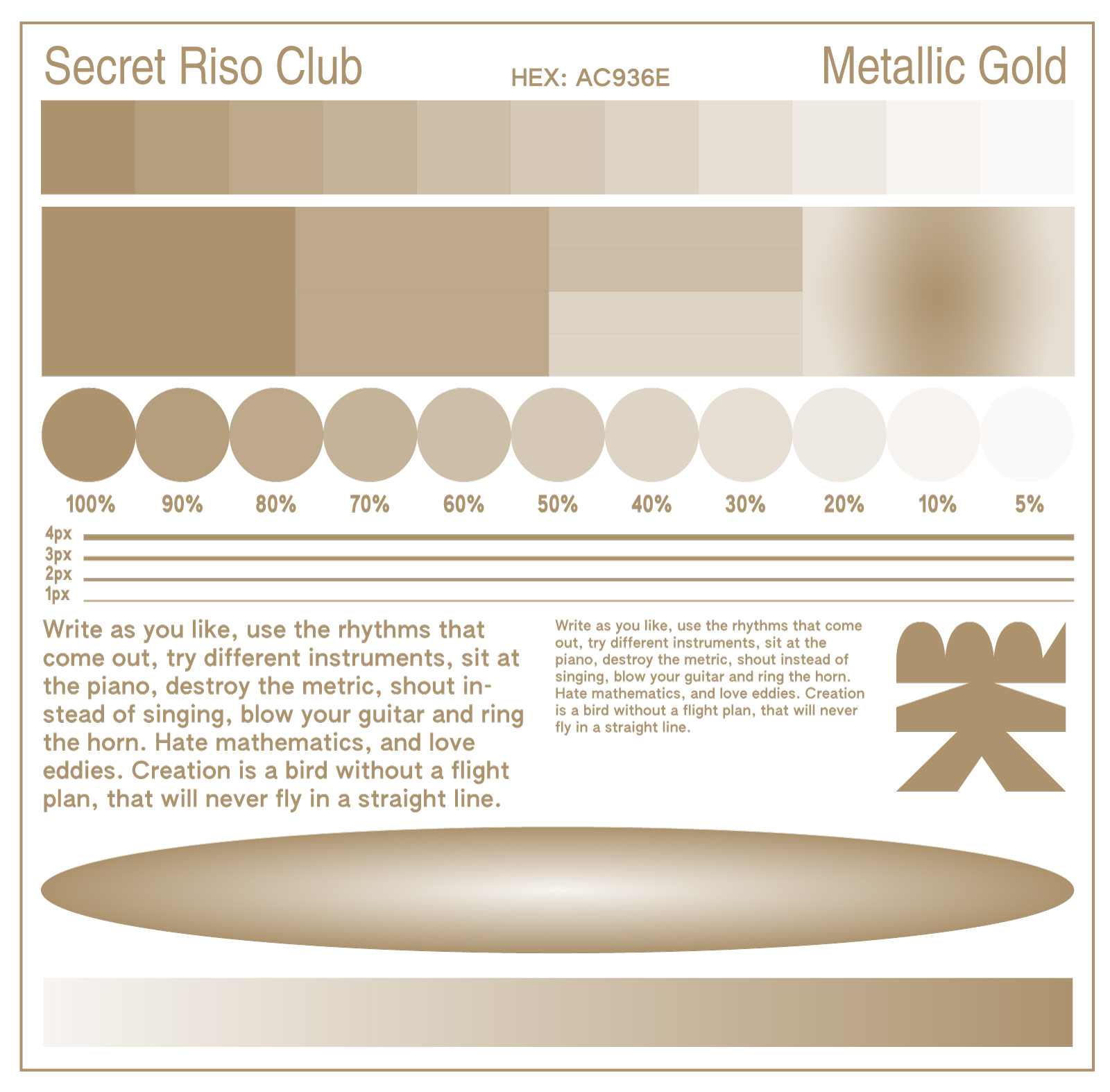

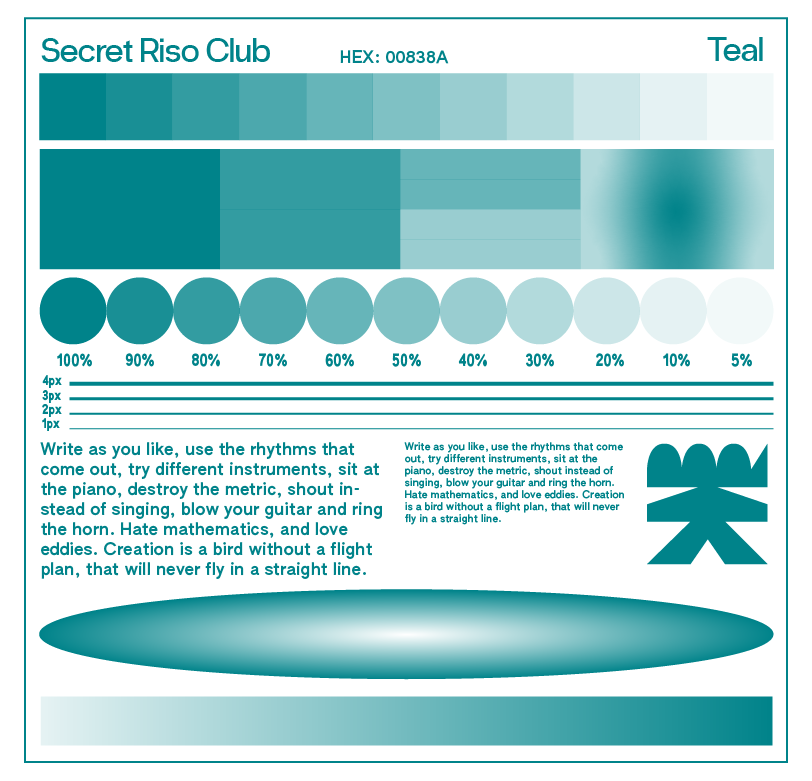

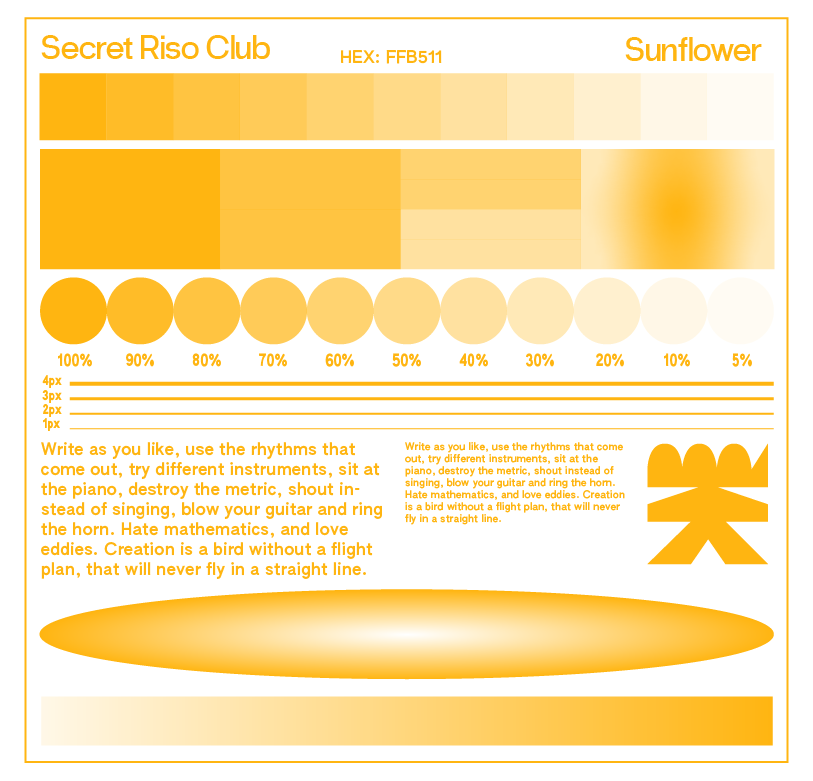

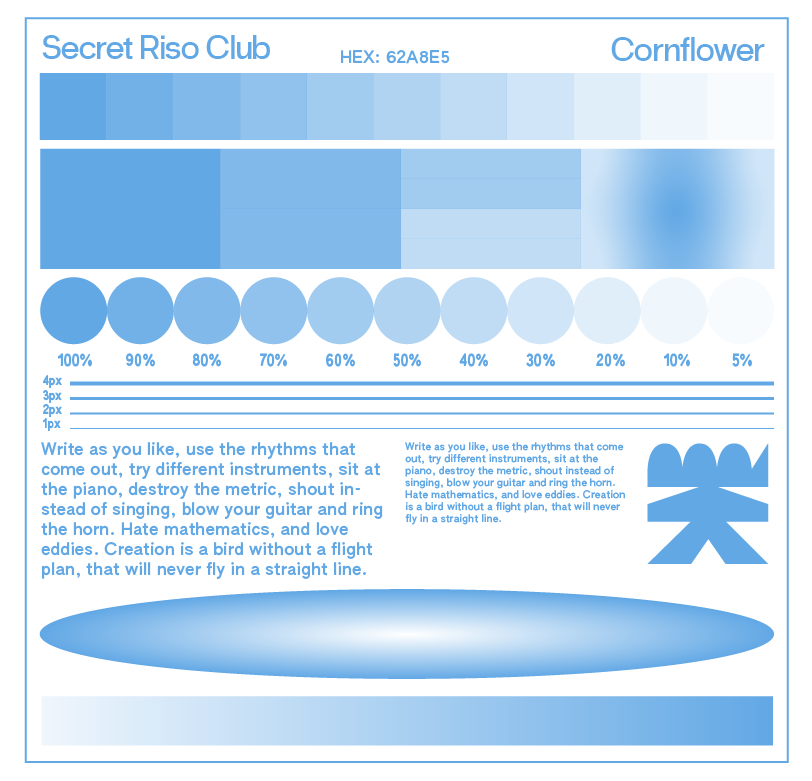

Ink / Riso Colors

We currently stock 19 inks total.

These colors can be blended to make new colors by layering and altering % of opacity.

*Gold ink has an additional cost.

︎︎︎Download our Riso color swatches for adobe & spectrolite here︎︎︎

- 15 inks for ours MF9450 machine (TWO DRUM): black, yellow, red, blue, violet, orange, fluorescent pink, green, bright olive green, light lime, aqua, fluorescent orange, burgundy, light gray, and metallic gold.

-

4 inks for EZ590 (ONE DRUM): cornflower, sunflower, teal, bubblegum.

These colors can be blended to make new colors by layering and altering % of opacity.

*Gold ink has an additional cost.

︎︎︎Download our Riso color swatches for adobe & spectrolite here︎︎︎

EZ591 MACHINE (ONE DRUM)

Printing Area

Riso can print up to 11x17 inches (tabloid) and down to 3.5”x5.5 inches.

Please note that Riso cannot print full bleed so you would need to add a 1/4 -1/2 inch border on prints and booklets.

Large areas of block color won't print out evenly, and will also cause print marks.

Maximum Size: Tabloid (11”x17”) Tabloid

Printable Paper Sizes: 3.5” x 5.5” to 12” x 17”

Printable area aprox.: 10.75" x 16.75"

We use standard U.S. paper size : 11x17 "Tabloid" and 8.5x11 “Letter”

︎︎︎Download tabloid 11x17” template here

Please note that Riso cannot print full bleed so you would need to add a 1/4 -1/2 inch border on prints and booklets.

Large areas of block color won't print out evenly, and will also cause print marks.

Maximum Size: Tabloid (11”x17”) Tabloid

Printable Paper Sizes: 3.5” x 5.5” to 12” x 17”

Printable area aprox.: 10.75" x 16.75"

We use standard U.S. paper size : 11x17 "Tabloid" and 8.5x11 “Letter”

︎︎︎Download tabloid 11x17” template here

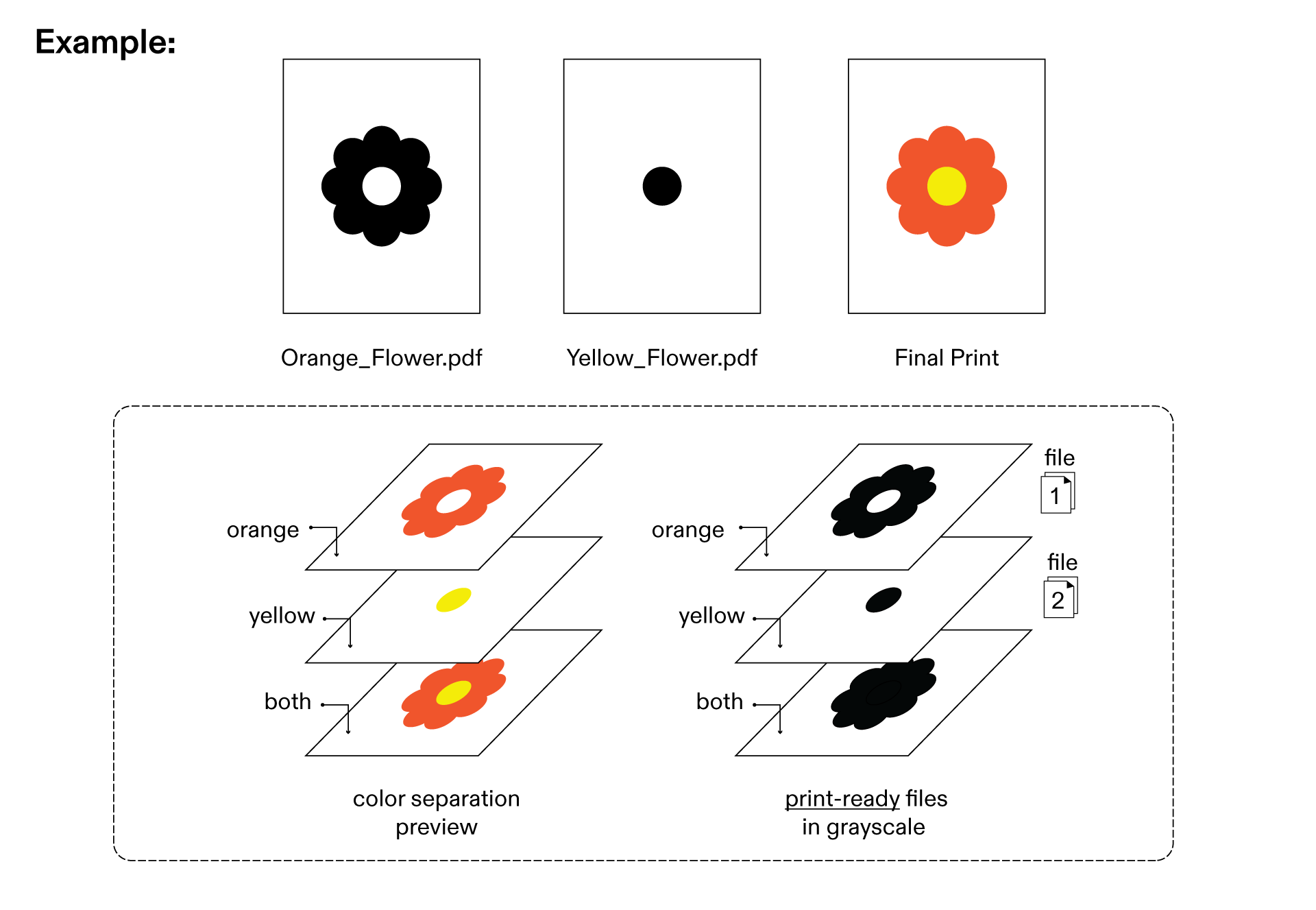

File Set-Up

To prepare your artwork for printing, you need to save each color layer as a separate grayscale file. All solid shapes, type and images should be set to Black (from 5% to 100% opacity).

If your project is full-bleed, include at least an 1/4 inch bleed area.

Please send us your work in PDF (High-res - 300-600 DPI), or Illustrator (package), PSD, Indesign (Package). Images in PDF must be JPEG, grayscale and 300dpi; no effects and no transparency.

Fonts cannot be smaller than 7pt and lines .5pt minimum.

Due to the quirks of Riso, avoid large areas of solid color (they should be at max 50% opacity). Be sure to send us a full color JPEG or PDF as a reference. If attempting to print large blocks for solid ink, coverage might vary slightly, and there may be differences in gradation.

If your project is full-bleed, include at least an 1/4 inch bleed area.

Please send us your work in PDF (High-res - 300-600 DPI), or Illustrator (package), PSD, Indesign (Package). Images in PDF must be JPEG, grayscale and 300dpi; no effects and no transparency.

Fonts cannot be smaller than 7pt and lines .5pt minimum.

Due to the quirks of Riso, avoid large areas of solid color (they should be at max 50% opacity). Be sure to send us a full color JPEG or PDF as a reference. If attempting to print large blocks for solid ink, coverage might vary slightly, and there may be differences in gradation.

Test Print

Running a test print or a proof is difficult because masters can’t be reused. For smaller scale projects, we can do a test print for an additional fee, and for larger projects like books, we can run a interior page and a cover test print if necessary for an additional fee.

Paper

Cover Stock:

60lb-100lb - 80lb Preferred.

Text Stock: must be between 60lb-100lb Text weight

Finish: Uncoated paper - Vellum or "Offset" finish preferred.

Riso can’t print glossi or coated paper.

60lb-100lb - 80lb Preferred.

Text Stock: must be between 60lb-100lb Text weight

Finish: Uncoated paper - Vellum or "Offset" finish preferred.

Riso can’t print glossi or coated paper.

Riso inks work on most uncoated papers, and do not work on any coated papers or tracing papers. If you are looking for a specialty paper stock, we recommend checking out French Paper Co, Mohawk, Glodan.

Maximum Size:

Tabloid

Printable Paper Sizes: 3.5” x 5.5” to 11” x 17”

Tabloid

Printable Paper Sizes: 3.5” x 5.5” to 11” x 17”

Printing Imperfections

Smudging

Riso ink is made of soy oil, water and pigment, so like newspaper ink, smudging is a possibility. Also, as Riso ink can smudge or rub off, it is preferable to avoid large block areas of color for flyers and covers, in particular bright colors. We can advise on how to make a project more smudge resistant.

Riso ink is made of soy oil, water and pigment, so like newspaper ink, smudging is a possibility. Also, as Riso ink can smudge or rub off, it is preferable to avoid large block areas of color for flyers and covers, in particular bright colors. We can advise on how to make a project more smudge resistant.

Ink Transfer

Heavy ink can lead to transfer between prints as the prints are stacked on top of each other as they exit the printer.

Heavy ink can lead to transfer between prints as the prints are stacked on top of each other as they exit the printer.

Roller Marks

Paper feeder rollers may leave marks on the page when a paper is run through the Riso multiple times and has heavy ink. This can be avoided by printing heavy inks last, and let them dry overnight. Print marks may also appear, but these can be easily rubbed off with an eraser if they are in a white area.

Paper feeder rollers may leave marks on the page when a paper is run through the Riso multiple times and has heavy ink. This can be avoided by printing heavy inks last, and let them dry overnight. Print marks may also appear, but these can be easily rubbed off with an eraser if they are in a white area.

Registration

Just as with screen printing, with Riso each ink color is layered on separately. That means a single sheet of paper will run through the machine multiple times for projects printing more than 2 layers, and the registration of color can be irregular.

Just as with screen printing, with Riso each ink color is layered on separately. That means a single sheet of paper will run through the machine multiple times for projects printing more than 2 layers, and the registration of color can be irregular.